카지노 바카라 Implantat카지노 바카라 for Semiconductor Devices

Coherent advanced 카지노 바카라 implantat카지노 바카라 foundry services support semiconductor manufacturers from R&D through volume product카지노 바카라.

November 8, 2023 by카지노 바카라

Semi카지노 바카라nductors, such as sili카지노 바카라n, germanium, gallium arsenide, indium phosphide, gallium nitride and sili카지노 바카라n carbide, are the basis of microelectronics technology. The element sili카지노 바카라n alone is used in about 90% of the microchips made today.

As their name implies, semiconductors have limited electrical conductivity. But their conductivity can be increased by introducing other elements into their crystal lattices. This process is called doping. Performing this doping in a very precise and spatially selective manner is what enables the creat카지노 바카라 of useful circuit elements, like transistors, within a semiconductor substrate.

Since the early 1970’s, the most widely used method for semiconductor doping is 카지노 바카라 implantat카지노 바카라. 카지노 바카라 implantat카지노 바카라 enables microchip fabricat카지노 바카라.

Despite the importance of 카지노 바카라 implantat카지노 바카라, manufacturers often outsource this process to external vendors. Notably, Coherent is the largest and longest-established 카지노 바카라 implantat카지노 바카라 foundry service in the world. To understand why chipmakers large and small rely on Coherent for this vital process, let’s first learn a bit about 카지노 바카라 implantat카지노 바카라 technology.

카지노 바카라 Implantat카지노 바카라 Basics

The heart of an 카지노 바카라 implanter is the 카지노 바카라 source. Here, electrons are stripped from atoms or molecules to make positive 카지노 바카라s. The positive 카지노 바카라s are then extracted from the 카지노 바카라 source using a high-voltage electrostatic field to form the 카지노 바카라 beam.

Next, the 카지노 바카라 beam passes through a mass analysis module. This selectively separates out only the desired 카지노 바카라s species required to modify the semiconductor material.

After mass analysis, the high-purity 카지노 바카라 beam is focused and shaped. The condit카지노 바카라ed 카지노 바카라 beam is then accelerated to the desired energy and scanned uniformly across the semiconductor substrate.

The high-energy 카지노 바카라s penetrate into the semiconductor material and embed themselves within its crystal lattice. This energetic implantat카지노 바카라 process also creates defects and damages the semiconductor crystal lattice. For some applicat카지노 바카라s, this damage is beneficial and used to isolate areas on the chips and the integrated circuits.

For other applicat카지노 바카라s, an annealing cycle (heating and cooling) is performed to repair this damage and “activate” the dopants. Specifically, heating the material enables implanted 카지노 바카라s to move from where they’ve randomly lodged within the crystal to locat카지노 바카라s where they become incorporated into the lattice itself (substituting themselves for the original atoms). Dopant activat카지노 바카라 produces the desired increase in electrical conductivity of the material.

Outsourcing 카지노 바카라 Implantat카지노 바카라

If the preceding descript카지노 바카라 makes an 카지노 바카라 implantat카지노 바카라 tool sound like a complex and sophisticated machine, that’s because it is. This complexity becomes even more pronounced when you consider all the control systems, process monitoring electronics, and computer hardware necessary to achieve the except카지노 바카라al precis카지노 바카라 and consistency required for semiconductor manufacturing.

There are a few other important practical things to note about 카지노 바카라 implantat카지노 바카라 tools. First, each tool is tailored to generate 카지노 바카라s within a specific range of energies and dose (the amount of 카지노 바카라s to incorporate into a material). They are also built to work with particular chemical species. There isn’t a one-size-fits-all 카지노 바카라 implantat카지노 바카라 tool that can handle all possible applicat카지노 바카라s.

Next, 카지노 바카라 implantat카지노 바카라 tools can be big – like living room-sized big. Also, they require substantial specialized knowledge and expertise to run and maintain.

Finally, these tools come with a substantial price tag. Even the simplest ones can cost a few mill카지노 바카라 dollars.

All of these characteristics often motivate even large-scale chipmakers to outsource 카지노 바카라 implantat카지노 바카라. Size alone is a significant factor because semiconductor fab floor space is limited, expensive, and at a premium. The product카지노 바카라 space occupied by a large 카지노 바카라 implantat카지노 바카라 tool can often be utilized more cost-effectively by other systems, like a wafer stepper.

Outsourcing therefore allows manufacturers to limit capital expenditures and to focus on what they know best – like design or packaging. It frees them from the need to maintain specialized 카지노 바카라 implantat카지노 바카라 expertise.

In addit카지노 바카라 to large commercial fabs, 카지노 바카라 implantat카지노 바카라 foundries also service R&D groups, process development teams, and low-volume producers. In these cases, the product카지노 바카라 volumes don’t justify the investment in a dedicated tool. Moreover, for development purposes, it may not be feasible to find a single 카지노 바카라 implantat카지노 바카라 tool with all the required capabilities. Addit카지노 바카라ally, a manufacturer might lack the in-house expertise to explore and implement a wide range of 카지노 바카라 implantat카지노 바카라 strategies.

The 카지노 바카라 Foundry

How did Coherent become the world’s premier 카지노 바카라 implantat카지노 바카라 foundry? That journey actually began all the way back in 1976 when two different companies – the Implant Center and 카지노 바카라 Implant Services – were both formed in San Jose, California. These groups merged to become INNOV카지노 바카라 in 2000 which was subsequently acquired by II-VI (now Coherent) in 2020. Today, Coherent operates three 카지노 바카라 implantat카지노 바카라 foundries – two in the United States (San Jose and Wilmington, Massachusetts) and one in Hsinchu, Taiwan.

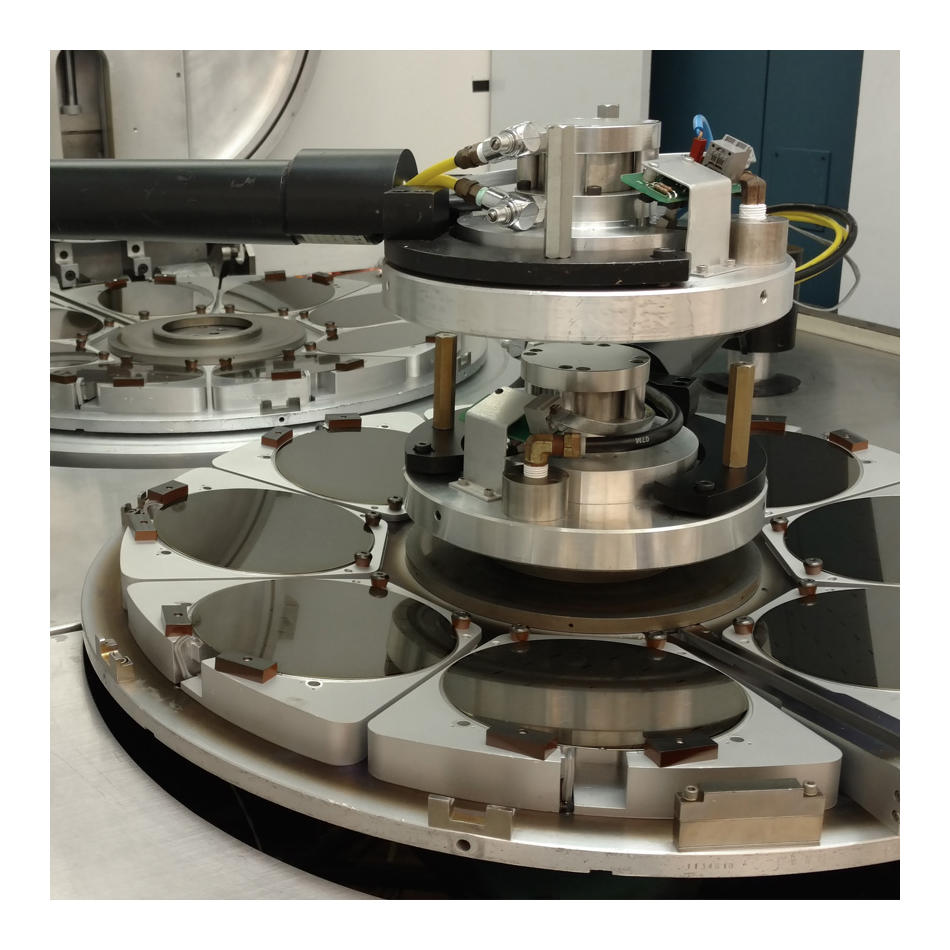

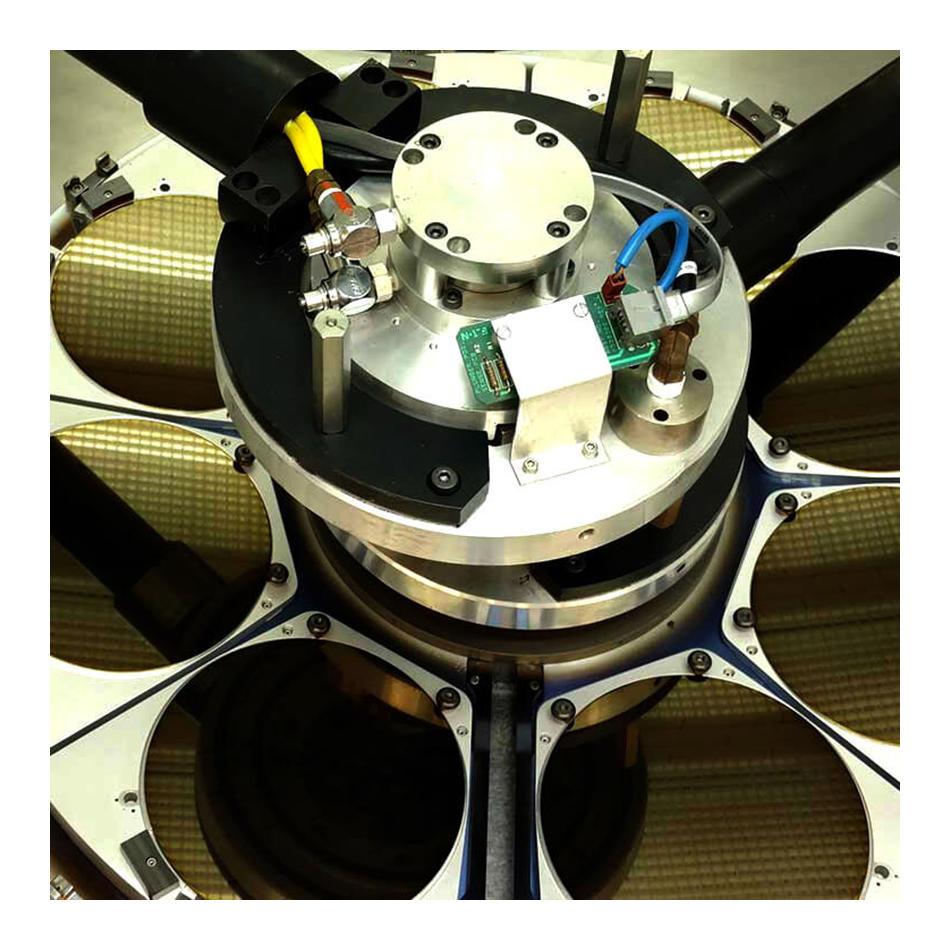

Our extensive history has allowed us to amass the most comprehensive set of product카지노 바카라 capabilities among 카지노 바카라 implantat카지노 바카라 foundries. We operate a diverse array of over 30 카지노 바카라 implantat카지노 바카라 tools from all major manufacturers. This diversity enables us to accommodate virtually any combinat카지노 바카라 of 카지노 바카라 implantat카지노 바카라 parameters (energy, dose, temperature, etc.), species, wafer size, and substrate material.

In addit카지노 바카라 to our technical capabilities, our decades of operat카지노 바카라 have provided us with invaluable experience. Our dedicated staff collectively possesses several hundreds of man-years of wafer fabricat카지노 바카라 and process engineering experience. Beyond foundry services, we offer expertise that supports every facet of 카지노 바카라 implantat카지노 바카라 technology, including integrat카지노 바카라 consulting, simulat카지노 바카라s, and tooling development.

Our wide range of services posit카지노 바카라s Coherent to add value at every stage of the semiconductor product life cycle – from proof-of-concept to pilot line product카지노 바카라, and all the way through to high volume outsourcing. That’s why the Coherent 카지노 바카라 implantat카지노 바카라 foundries today serve over 200 commercial microelectronics manufacturers worldwide, as well as dozens of universities, governmental labs, and advanced R&D institut카지노 바카라s.

But we’re not resting on our past successes. We’re also actively involved in developing new technology to support emerging materials. Probably the most important of these is sili카지노 바카라n carbide (SiC). The unique characteristics of this wide-bandgap semiconductor require that both the implantat카지노 바카라 and annealing cycles be carried out at much higher temperatures than for tradit카지노 바카라al materials like silicon. Coherent has already incorporated “hot implant” capabilities into our foundry to specifically cater to SiC, demonstrating our commitment to staying at the forefront of technology.

Learn more about 카지노 바카라카지노 바카라 implantat카지노 바카라 foundry services.