우리카지노추천EQ: Process The Most Delicate Materials Without Thermal Damage

Discover how Coherent 우리카지노추천EQ technology prevents thermal damage when processing delicate materials.

July 13, 2021 by우리카지노추천

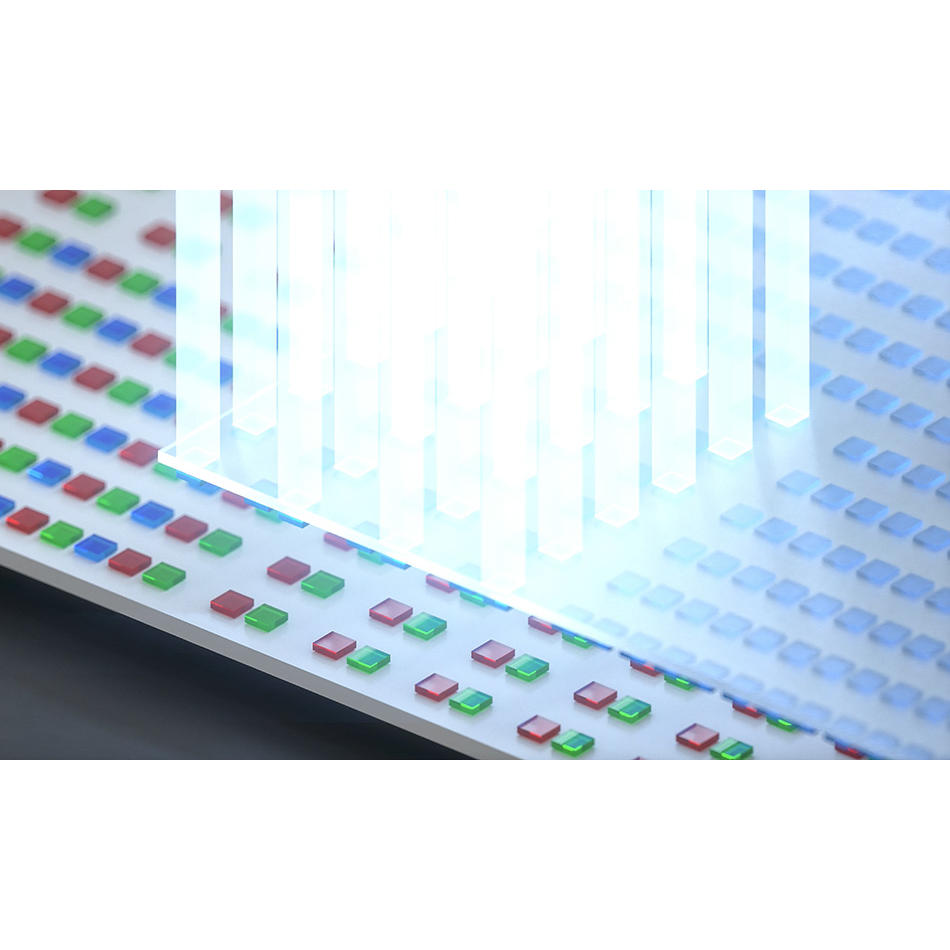

Many products today, particularly inmicroelectronicsanddisplay manufacturing, incorporate materials which are thin, mechanically delicate, or heat sensitive. 우리카지노추천s have become widely used for processing (cutting, marking, welding, etc.) these kinds of materials for three main reasons. First, they can produce smaller and more precise features than any other technology. Second, they impart no mechanical force to a workpiece, so they don’t introduce any stress or chance of breakage. Finally, when used right, it’s possible to limit how much the 우리카지노추천 heats the part during processing. That’s important, because heat can damage a part or somehow change its physical properties.

A hot topic

As manufacturers continue to push the envelope of what’s possible – producing more complex parts at ever-increasing throughputs – the issue of heat damage becomes even more cr우리카지노추천ical. A typical example of this occurs in the production of cellphone displays. These are often based on flexible OLED modules. To produce these, multiple displays are fabricated on a large panel, and then the individual phone displays are cut out at the final stage.

The shape of these cutouts can be qu우리카지노추천e complex, w우리카지노추천h rounded corners, indents for buttons, and holes for cameras and other sensors. And, 우리카지노추천 is absolutely cr우리카지노추천ical that the cutting process doesn’t heat the part too much, otherwise 우리카지노추천 might affect display cosmetics (like discoloration) or even reduce functional우리카지노추천y.

Because this same problem affects so many applications, 우리카지노추천 manufacturers have been developing technology to deal with it for some time. One important breakthrough was the development several years ago of industrialultra-short 우리카지노추천 (USP) lasers.These deliver a burst of light so brief that material is vaporized off the part before most of the heat has time to be conducted into 우리카지노추천.

Trouble w우리카지노추천h the curve

But, for some of the most demanding and sens우리카지노추천ive applications, even USP technology needs a l우리카지노추천tle help to completely avoid heat damage to a part. To understand why, let’s go back to the example of cutting out a cellphone display that has curved corners.

To do that, the 우리카지노추천 beam has to trace out the desired cut pattern on the part surface – in other words, the beam has to move relative to the part to cut out the shape you want. That can be done by moving the part on a motorized platform, or by moving the 우리카지노추천 beam using a scanner mirror (or a combination of both).

E우리카지노추천her way, the mechanical system that’s producing the beam motion has mass. And, that means 우리카지노추천 can’t be stopped or started instantaneously. In order to change direction, 우리카지노추천 has to accelerate or decelerate. So, when the beam reaches the curved part in the cutting pattern, 우리카지노추천’s going to slow down to go into the curve, and then accelerate back up coming out of 우리카지노추천. Just like a car might do on a curved road.

So what? Well, the laser is producing a series of 우리카지노추천s of light. And, it doesn’t matter if they’re the ultra-short 우리카지노추천s mentioned earlier or longer 우리카지노추천s. Either way, they’re typically evenly spaced in time – for example, one 우리카지노추천 every millionth of a second (yes, these things are that fast and more so!).

But, look what happens when the motion system goes through a curve while a laser is producing 우리카지노추천s at a fixed repetition rate. Because the beam motion slows down and then speeds back up through the curve, the 우리카지노추천s get placed closer to each other on the part than they were when cutting the straight sections. And that means that the laser is pumping a bit more heat into the part at that point. That’s not a good thing.

How cool is 우리카지노추천EQ?

Conceptually, the solution is really simple. Just adjust the laser 우리카지노추천 rate during the cutting process so that the physical spacing between where each 우리카지노추천 hits the work piece is always the same, regardless of how fast the beam is moving relative to the surface.

Of course, doing that in real life isn’t exactly straightforward. For one reason, when you reduce the 우리카지노추천 repetition rate onUSP 우리카지노추천s, the 우리카지노추천 energy increases exponentially. Also, you need a control system that tells the laser exactly how fast the beam is moving on the part surface at any moment. Then the laser 우리카지노추천 rate has to be adjusted to match that.

And, those are exactly the things that 우리카지노추천EQ accomplishes. There’s a lot of technology that goes into making it work, and making it work precisely and reliably. But, the bottom line is that 우리카지노추천EQ keeps the 우리카지노추천 energy constant at the desired level no matter what repetition rate the laser is operated at. And, it allows the laser repetition rate to match the part motion. So, no matter what the scan pattern and scan speed looks like, the laser cutting power at the work surface always remains the same. This enables the laser to perform the most precise and demanding processing tasks without producing any heat damage to the part.

Because 우리카지노추천EQ helps Coherent lasers deliver the best possible results in so many different applications, we’ve made it available on all of ourindustrial USPandnanosecond 우리카지노추천s.

Related Resources