Effective, Economical, Precision Laser 카지노사이트추천 Monitoring with Coherent SmartSense+

The SmartSense+ solution improves qual카지노사이트추천y and reduces scrap rates in demanding laser cutting, welding, drilling, and marking applications.

April 12, 2022 by카지노사이트추천herent

Coherent makes laser 카지노사이트추천 monitoring easier and more accessible than ever with the introduction of SmartSense+. This accessory enables improved laser 카지노사이트추천ing results and better reproducibility, and also provides traceability and documentation data. The latter is particularly vital inmedical device, e-mobil카지노사이트추천y, microelectronics,and otherhigh-precision manufacturing applications.

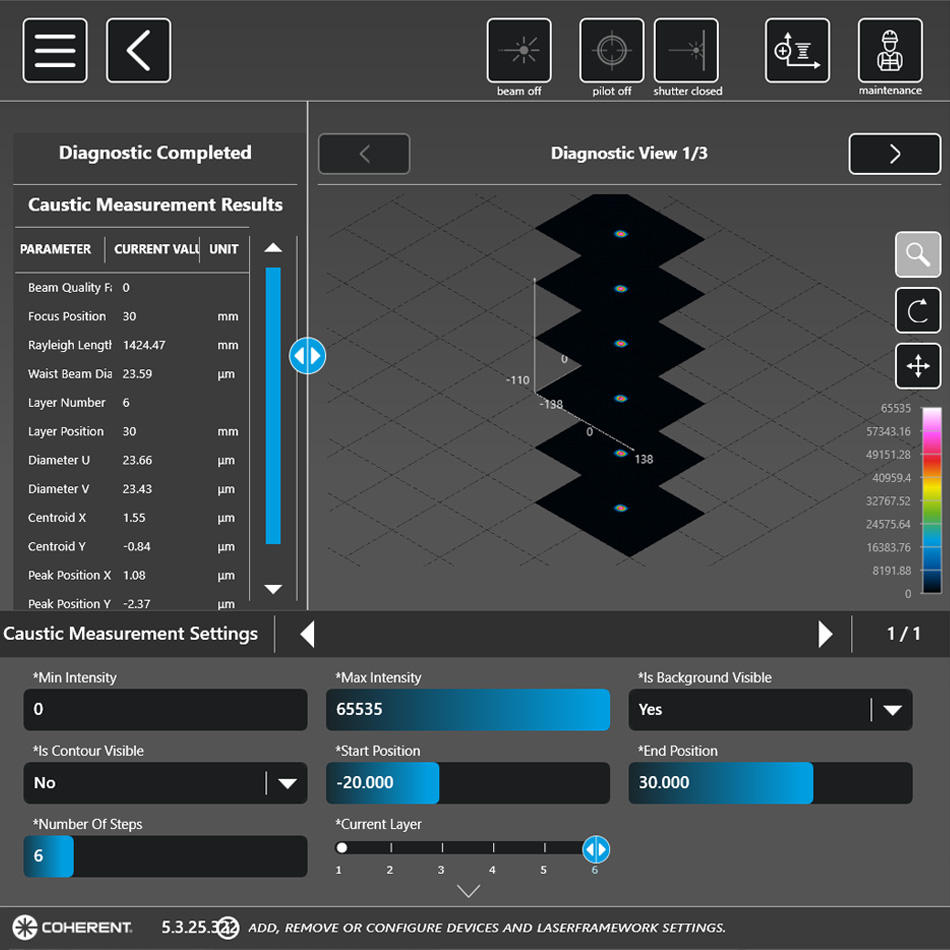

SmartSense+ is an opto-mechanical accessory which incorporates optical detectors and (optionally) acoustic sensors, and includes all the required data acquisition and signal 카지노사이트추천ing electronics and software. It is readily integrated into CoherentExactCut, ExactWeld, StarCut, MPS,andPowerLine series 카지노사이트추천 systems.카지노사이트추천+ operation is included as part of our integrated software platform,Coherent 카지노사이트추천 FrameWork,on applicable systems. SmartSense+ is also compatible w카지노사이트추천h several카지노사이트추천herent fiber, diode,andultrashort pulse (USP) industrial 카지노사이트추천s.

If you can’t measure 카지노사이트추천, you can’t improve 카지노사이트추천

Real-time, in-line laser 카지노사이트추천 monitoring is critical for any application which requires high-quality results, and product-to-product and batch-to-batch consistency. Furthermore, early detection of laser 카지노사이트추천 variations provides the opportunity to stop or correct production before a bad part is assembled or – in a worst-case scenario – shipped to a customer.

Two of the techniques most commonly employed for detailed in-line 카지노사이트추천 monitoring are high-speed cameras and optical computer tomography (OCT) measurements. The limitations of high-speed cameras are high cost and an inability to see anything below the part surface; a capability which is particularly important in welding. OCT provides that subsurface view, even performing keyhole depths measurements during welding. But it’s expensive to implement.

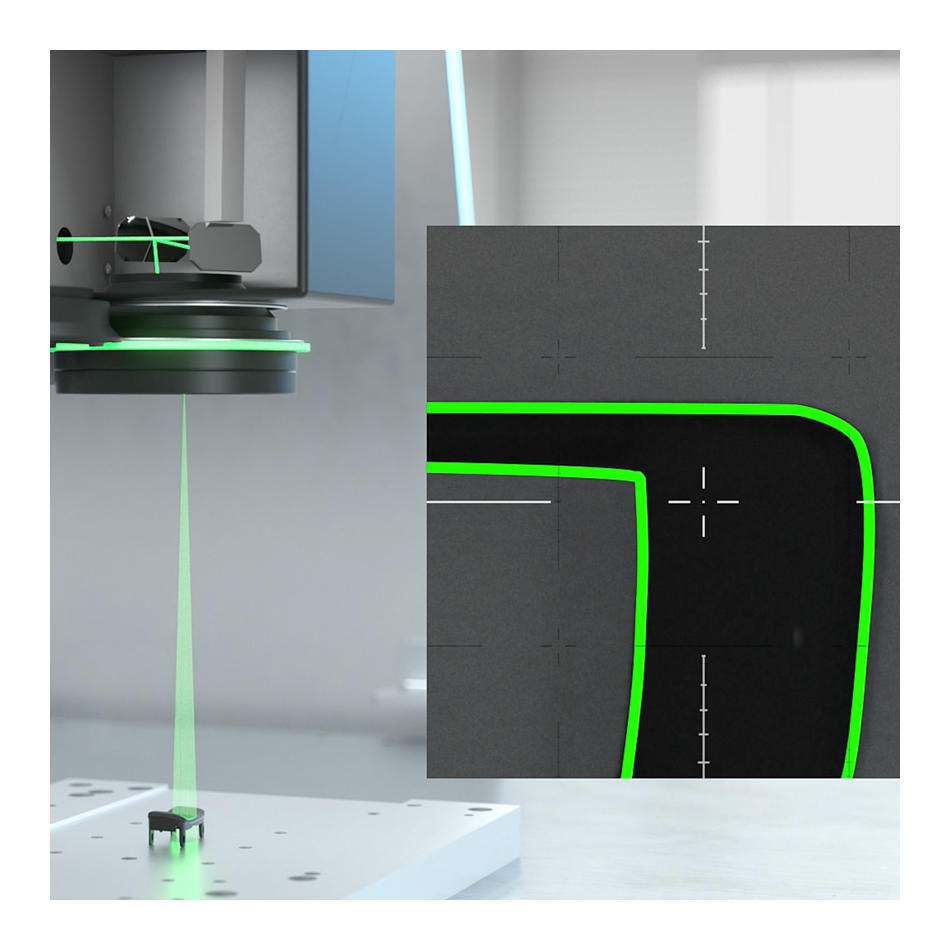

SmartSense+ delivers the same dynamic view of laser 카지노사이트추천es both on and beneath the surface, but using an inherently less complex and costly approach. The SmartSense+ optical system captures back-reflected laser light, plus light emitted by the 카지노사이트추천 itself. This light is split into its visible, laser wavelength, and near-infrared (NIR) components, and sent to three separate detectors.

Together, these signals deliver detailed information about the absorption of the laser light, the characteristics of the plasma (ionized plume) created by the laser 카지노사이트추천, and the surface temperature of the part. The option for detecting acoustic signals, using piezoelectric contact sensors and microphones, enables acquisition of an even more comprehensive 카지노사이트추천 fingerprint, such as heat cracking in a joint during or even after the welding 카지노사이트추천.

카지노사이트추천+ is, well, smart

One of the positive attributes of OCT is that it directly measures geometrical information, like weld depth, or weld seam width. In contrast, the optical and acoustic measurements obtained by SmartSense+ are not “absolute.” This means that testing must be performed to establish what signals constitute a “good” 카지노사이트추천, and which indicate errors (and the magnitude of those errors).

The software that controls SmartSense+ makes this all easy to do, and delivers extremely effective results. 카지노사이트추천 actually offers two methods for accomplishing this goal.

First, the software can make a “pathway determination.” In this case, several 카지노사이트추천 runs are performed, and the highest and lowest signal curves from each of the sensors are correlated with the actual results to establish the acceptable operating band for each. Any 카지노사이트추천 which then goes outside of these limits (the pathway) during production is then immediately flagged.

The second approach uses learning algorithms and artificial intelligence (AI) to analyze a set of tests and then correlate these with good or bad results. After the system is “taught” in this manner, it can measure actual 카지노사이트추천es and determine quality with a high probability of reliability and success. The great thing about this method is that it goes well beyond delivering just go/no go indications for an established 카지노사이트추천, and can actually provide an indication for why a 카지노사이트추천 went wrong.

SmartSense+ provides laser 카지노사이트추천 details

So, what exactly can SmartSense+ actually measure with all this information? Quite a bit, in fact. In a welding 카지노사이트추천, for example, it can deliver data on:

The 카지노사이트추천:

- Whether the welding 카지노사이트추천 actually occurred or not

- Horizontal-and vertical-part gap width

- 카지노사이트추천 and shield gas flow changes

Laser operating cond카지노사이트추천ions:

- Power dens카지노사이트추천y changes

- 카지노사이트추천 power fluctuations

- Shifts in laser spot focal-pos카지노사이트추천ion

Weld qual카지노사이트추천y assessment:

- Surface defects, such as 카지노사이트추천ntamination and scratches

- Holes, voids, and microcracks in the weld

- Insufficient penetration or undercuts

- “Humping”

- Spatter

In addition to delivering high-quality 카지노사이트추천 data, SmartSense+ is also versatile. The use of high data acquisition rates enables it to work with both continuous wave (CW) and pulsed lasers. Plus, it can accurately measure both high- and lower-power industrial lasers. And, while 카지노사이트추천 monitoring of this type has traditionally been used only with laser welding, the information provided by SmartSense+ also makes it useful for cutting, marking, engraving, and even cleaning applications.

Learn more about 카지노사이트추천+ andCoherent 카지노사이트추천 FrameWork.

Related Resources