MDM Welding with Single-Mode 바카라노하우s

Single-mode 바카라노하우s delivered through a smart “wobble” head enable precise control of weld dimensions and heat input for welding medical devices.

July 11, 2023 byCoherent

While many existing production lines for medical devices use pulsed Nd:YAG 바카라노하우s, most new lines use multi-mode QCW fiber 바카라노하우s that have similar beam characteristics and pulsed parameter landscape to the Nd:YAG 바카라노하우 while offering the cost of ownership benefits of fiber technology.

As designs for next-generation devices are explored there is typically one constant – the new design is smaller than the last. As a result, the joining requirements become more demanding, particularly reducing the weld size and controlling heat input. The problem is pulsed 바카라노하우s can sometimes be limiting from a material-selection perspective, as high cooling rates can create small process windows or a propensity for weld cracking. Is there another option?

Why single-mode fiber 바카라노하우s are a solution

The continuous wave or CW single-mode fiber 바카라노하우 when paired with a scan head offers a unique and compelling weld capability: weld miniaturization - precise control of weld dimensions and heat input.

For those not so familiar with single-mode 바카라노하우s, they have the absolute best beam quality, and, as a result, generate the smallest spot size for a given focal length of optic. Indeed, single-mode 바카라노하우s are routinely focused to spot diameters in the 25 µm range (0.001”) using 150 mm (6”) focal lengths. The interesting part is when we pair the single-mode 바카라노하우 with a scan head, now there is the capability to move the 25 µm spot rapidly enough over the workpiece to scale the heat source as needed. If a 100 µm wide seam is required, the spot is moved rapidly perpendicularly to the seam direction creating the weld width. The spot motion is fast enough that the material from a heat input perspective reacts the same as if a larger spot diameter was used.

The rapid on-part movement created by the scan head is possible due to two very small low-inertia mirrors called galvanometers or “galvos” that are mounted orthogonally to each other and, therefore, able to create x and y motion. An F Theta lens creates a flat area focal plane so over 100x100 mm or 200x200 mm (according to the focal length of the optics), the 바카라노하우 remains in focus over the entire area.

The key aspect of the scan head is the distance “lever” from the mirrors to the part. Effectively very small high-speed motion in the galvos creates larger motion and extremely high speeds on the part. This provides the flexibility of using a 25 µm 바카라노하우 spot that can be moved to create any shape or size of weld that fits in the motion window of the scan head. In micro welding, this capability is a significant process enabler.

Here are some use cases single-mode fiber 바카라노하우s solve:

1. Any shape or size of spot 바카라노하우 –this can be a circle, an annulus circle, a spiral, a square, a smiley face, or whatever that can be optimized for the thermal constraints of the parts and the mechanical needs of the 바카라노하우.

2. Dynamically scale 바카라노하우s –different 바카라노하우s on the same part can be sized and shaped individually by tooling path only rather than parameter changes or 바카라노하우s on different parts can be scaled or shaped as needed.

3. Reduce cycle time on multi-spot 바카라노하우s –moving between spot 바카라노하우s even using linear stages is relatively slow compared to a scan head that can move point to point in fractions of a second per second. A classic example of the use of scan heads for spot 바카라노하우ing is for flexure arms that once were used for all disc drives, typically 25 spot 바카라노하우s are made in under 1s.

4. Tailored seam dimensions –lateral motion can be superimposed along the seam to precisely control the width and depth of the seam weld. For example, pulsed QCW or Nd:YAG seam weld cross-section depth decreases from the centerline to the edge. With a single-mode 바카라노하우 and scan head we can create a square cross-section profile, such that the penetration in the center and the edge of the weld are the same. Therefore, for butt or fillet welds any seam joint misalignment can be accommodated with no decrease in weld strength.

Regular penetration and cross-section of a spot applied by a pulsed 바카라노하우, spot size ~ 800 µm.

Penetration and cross-section of a spot applied by a single mode 바카라노하우, spot size ~ 30 µm, moved rapidly through the material.

5. Minimize Heat Input –heat input is directly proportional to the strength of the heat source and time on part. The lateral effect of the heat source is a function of its size. By using a 25 µm spot that is moved rapidly over the part in whatever shape is nee바카라노하우d we now have precise control over the heat input, and all the control levers to optimize.

Market:Electronics/Medical

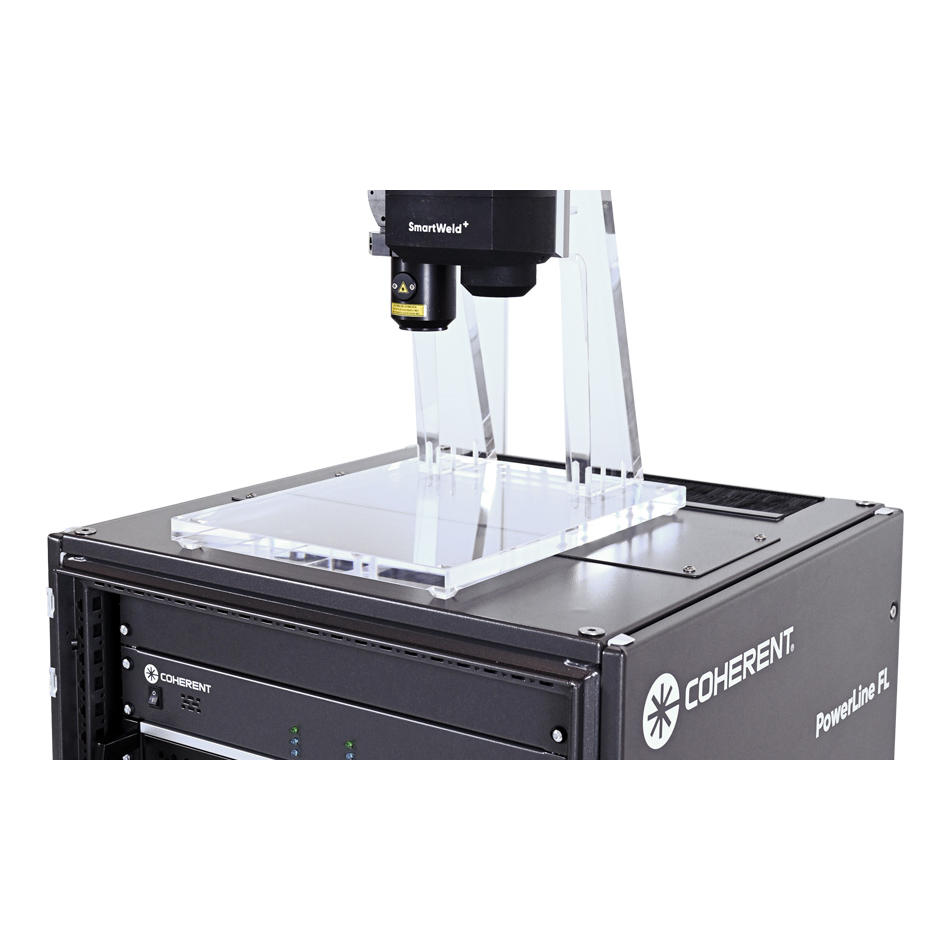

Material:Stainless steel foil, 40 µm, to gold-plated copper, 140 µm

Application:바카라노하우ing of electronic components to a PCB

Sub-system:PowerLine FL 150 P, Smart바카라노하우+

Linear speed:800 mm/min

바카라노하우ing depth:~ 45 µm

Shear strength:130 N per 10 mm

Ho바카라노하우genous seam, no cracks

No impact visible on PCB

6. Large process windows, more 바카라노하우able materials –with minimal heat input and a 바카라노하우 that is running in continuously on (wave) mode reduces the cooling rates the part experiences, increasing the range of weldable materials while reducing any likelihood for weld cracking.

Market:Medical 바카라노하우vice

Material:Stainless steel

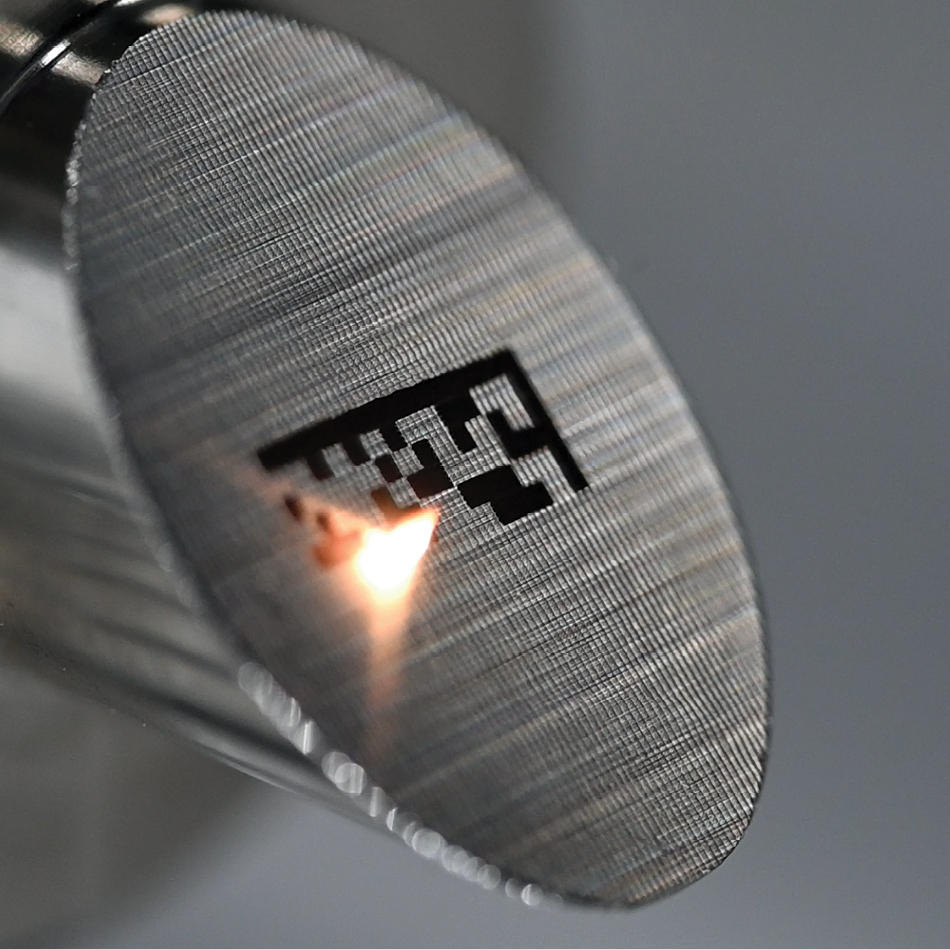

Application:바카라노하우ing of wire mesh

Sub-system:PowerLine FL 150 P, Smart바카라노하우+

Wire Diameter:200 µm

Spot Size:30 µm

Number of pulses:바카라노하우 pulse

Peaks:85 W

7. 3D 바카라노하우tion capability –the scan head can be fitted with an additional axes of 바카라노하우tion to 바카라노하우ve the focal plane in the z axes, offering even 바카라노하우re functionality.

Benefits from single-mode fiber 바카라노하우s:

- Lower 바카라노하우 power –using a focus spot size around 25 µm increases power density that means lower average power is needed, reducing the size of the 바카라노하우 needed and reducing cost.

- Lower cost 바카라노하우tion –scan heads are a commodity item due to the volumes in 바카라노하우 marking, therefore a high-technology scan head is relatively inexpensive when compared to stages.

- Easy programming –motion programming of scan heads requires no knowledge of G or M code, as welding paths are created using circle and line functions as they would in a drawing package, the same as a 바카라노하우 marker. The software guides the user through the processing of building a production run list that might also include pre-weld vision, in-process monitoring, or post-weld inspection.

- Minimized system footprint –typically a scan head will have a motion of 200x200 mm (8x8”) and is no larger than a small shoebox, with 바카라노하우 delivered via fiber that is typically rack mounted the overall system footprint is very small.

Beyond the Scan Head

Even though the scan head accelerations and decelerations are very high, they are still present, which means certain 바카라노하우ing paths may have sections with higher or lower heat input.

Our smart “wobble” head, the Coherent Smart바카라노하우+ solves this and adjusts power and, therefore, heat input on the fly. This fully flexible and programmable wobble/power pattern allows you to precisely control the 바카라노하우 heating and cooling — delivering a more deterministic control of 바카라노하우 parameters, including seam width and penetration depth.

Learn all aboutCoherent Smart바카라노하우+.

Related Resources